Seasonal Tire Changes

Your Lucid Gravity may use 22/23" summer tires and 20/21" winter tires. Several vehicle systems rely on knowing the wheel size, so a system update is required whenever swapping wheels of different sizes.

Wheel Swap Preferred Method: Lucid Service Center

If possible, it is best to schedule your wheel swap with a Lucid Service Center. They will complete the entire procedure for you, including making the physical swap, resetting the TPMS, and updating the vehicle software to recognize the new wheel sizes.

Swapping the Wheels Yourself

Depending on where your seasonal tires are stored, you may find it more convenient to perform the swap yourself. After you swap the wheels, you must update the vehicle software. You may do this yourself by following the prompts on the Pilot Panel or schedule a visit with Lucid Service Center to complete the procedure.

Whenever swapping a different tire size, the tire size information must be updated. To do this:

- Go to Settings

> Vehicle

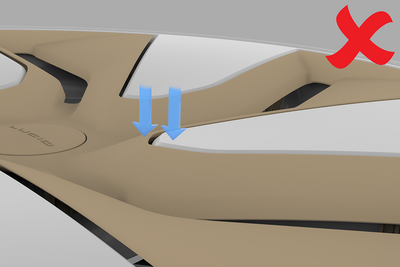

> Vehicle  .

. - Open Tires page.

- Choose Select Installed Tires page.

- Enter your Profile PIN.

- Choose Select Front Tires or Select Rear Tires.

- Select the new tire size.

Tire Swapping FAQs

- After swapping tires, the tire

pressure information is not displayed correctly.

The vehicle must be driven about 10 minutes for the TPMS information to get updated.

- The newly installed tire size

does not show up in the list of available tire sizes.

The new tire size is not approved by Lucid. Only Lucid-approved tire sizes should be installed. See Contacting Lucid Motors for more information.

- An error occurs when attempting

to update the tire size.

Wait a few minutes, then try again.